News

How to Quickly Distinguish NCM VS LFP Batteries Without Labels?

Why Identifying Battery Chemistry Matters

It’s extremely important to correctly figure out the type of lithium-ion battery. This is crucial for ensuring safety, optimizing performance, and following regulations. NCM (Nickel Cobalt Manganese) and LFP (Lithium Iron Phosphate) batteries may look pretty much the same on the outside. However, they are very different in terms of energy density, thermal stability, and what they’re suitable for. If you misidentify them, it could cause damage to devices, make them less efficient, or even create safety risks, especially in high - demand systems like energy storage setups or components in electric vehicles.

Physical Characteristics for Preliminary Assessment

Even though battery casings often don’t have any markings, there are some small physical differences that can help. NCM cells usually have a slightly darker metallic color compared to the matte gray surface of LFP batteries. Comparing their weights is also a good way. Because NCM has a higher energy density, a 18650 NCM cell weighs around 45 grams, while an equivalent LFP model weighs about 48 grams. Also, check the terminal configurations. Many LFP batteries come with standardized industrial connectors, which are commonly used in renewable energy applications.

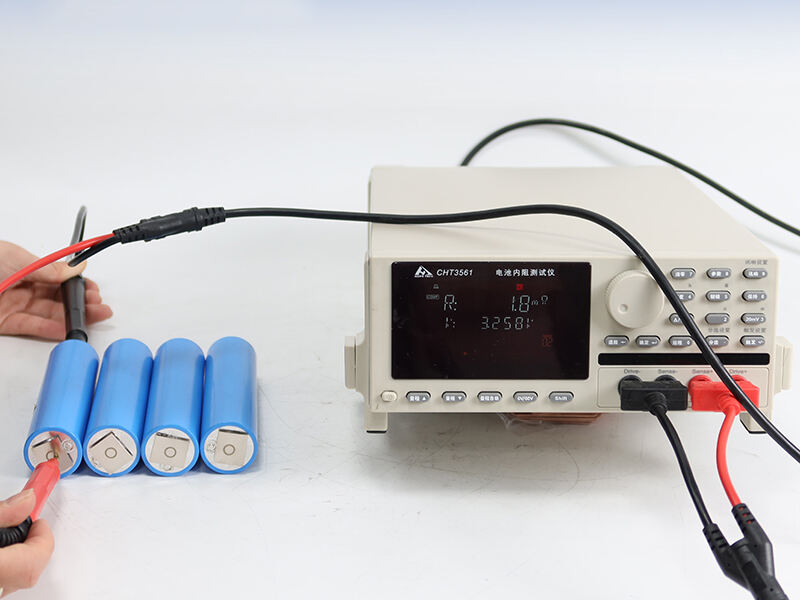

Voltage Profile Analysis Techniques

One way to tell the difference is by using a multimeter to measure the open-circuit voltage. When fully charged, NCM batteries show a voltage of 4.2V plus or minus 0.05V. In contrast, LFP cells reach a peak of 3.6V plus or minus 0.05V. Their discharge patterns are also quite different. NCM batteries can maintain a nominal voltage of 3.7V until they’ve discharged about 80% of their capacity, after which the voltage drops sharply. On the other hand, LFP batteries can sustain a nominal voltage of 3.2V and the voltage reduces more gradually. When it comes to identifying battery packs, count the number of series cells. In applications with similar voltages, LFP systems often use 32 - cell configurations, which result in 102V, while NCM systems usually have 24 - cell arrangements, reaching 88V.

Advanced Chemical Verification Methods

If visual and electrical tests aren’t enough to determine the battery type, you can conduct non - destructive material analysis. X-ray fluorescence (XRF) scanners can detect the elemental signatures. NCM batteries show peaks of nickel and cobalt, while LFP batteries have an iron and phosphorus spectrum without these nickel/cobalt peaks. Thermal imaging during low - rate discharge (0.2C) can also help. LFP batteries have better heat distribution, with a temperature variation of less than 5°C, while NCM batteries have a temperature gradient of 8 - 12°C. These methods meet the IEC 62619 standards for verifying industrial batteries.

Safety Protocols for Unknown Batteries

When you have an unidentified battery, keep it in a fire - rated container until you can classify it. When testing, wear protective gear and use current - limited chargers (no more than 0.1C). If you suspect it’s an LFP cell, make sure it’s compatible with lithium ferro phosphate chargers. For suspected NCM batteries, closely monitor the voltage. Overcharging them beyond 4.25V could lead to thermal runaway. And always follow the UN38.3 transportation guidelines when storing or shipping these batteries.

Application-Specific Identification Strategies

The way you identify batteries can also depend on the application. In the automotive field, measure the cold cranking performance. LFP batteries can maintain more than 80% of their capacity at -20°C, while NCM batteries only keep 50 - 60% of their capacity at that temperature. For solar installations, conduct cycle life tests. LFP batteries can usually withstand more than 3,000 cycles, while NCM batteries can only handle 1,500 - 2,000 cycles. Industrial users should carry out ASTM F2931 - 19 compliance checks, especially for critical infrastructure applications that require UL 1973 certification.